Capabilities

Lighthouse helps renewable energy developers reach financial investment decision by providing:

- Strategic grid connection advisory services

- Wind and solar resource measurement services for evaluation campaigns

Lighthouse also provides services to support the construction of wind, solar and battery assets:

- Early works services (site clearing and access)

- Foundation and civil construction works

- Permanent Met mast manufacture, install and maintenance

Lighthouse helps renewable energy developers to plan and deliver smarter connection infrastructure.

- End-to-end connection agreement services

- Design, construction & commissioning of electrical and civil balance of plant

- Earthworks, foundations and trenching

- Substation construction

- Pre-fabricated transportable switchrooms

- Transmission tower and monopole construction

- HV powerline stringing services

- Testing & commissioning

- Earthworks, foundations and trenching

Lighthouse supports transmission network service providers and their partners deliver critical network projects by providing skilled resources and solutions for:

- Site clearing & earthworks

- Foundations

- Tower & pole assembly and erection

- Conductor stringing

- Install hardware / running blocks

- Perform run out of draw wire and pull conductors

- Installation of earth wire and optical ground wire

- Termination of conductors / earth wire and clamping in

- Substation construction

- Testing & commissioning

- Maintenance

Electrification is critical for large manufacturing, industrial and resources clients to decarbonise. This results in larger grid connections. Lighthouse supports the decarbonisation of large industrial and digital loads by streamlining this complex process:

- Strategic grid connection advisory services

- Engineering, design and construction capability for brown and greenfield grid connections

Lighthouse provides a range of solutions to assist off grid clients design, deliver, operate and maintain infrastructure to support their rapidly changing energy needs.

- Wind monitoring for remote resources clients

- Civil and electrical turnkey balance of plant services for off grid power infrastructure

- Remote area microgrid management and operation

- Rapid deploy power and communication units

Integrated and end-to-end solutions across the entire project lifecycle

Strategic Planning & Feasibility

Our strategic planning and feasibility services support renewable energy developers manage project risk and capture opportunities to strengthen business cases. We are a partner for clients to set up projects early for success.

Our key offerings include:

Grid Connection Advisory & Services:

Leveraging over 50 years of combined grid connection experience, our portfolio company Clutch is the industry's trusted partner in grid connections.

- Assist clients in setting tailored strategies to navigate grid complexity, manage grid connection risks and seize connection opportunities.

- Lead the grid connection process, providing end-to-end services, leadership, increased visibility, cost & schedule alignment and an experienced partner.

Resource Evaluation Services:

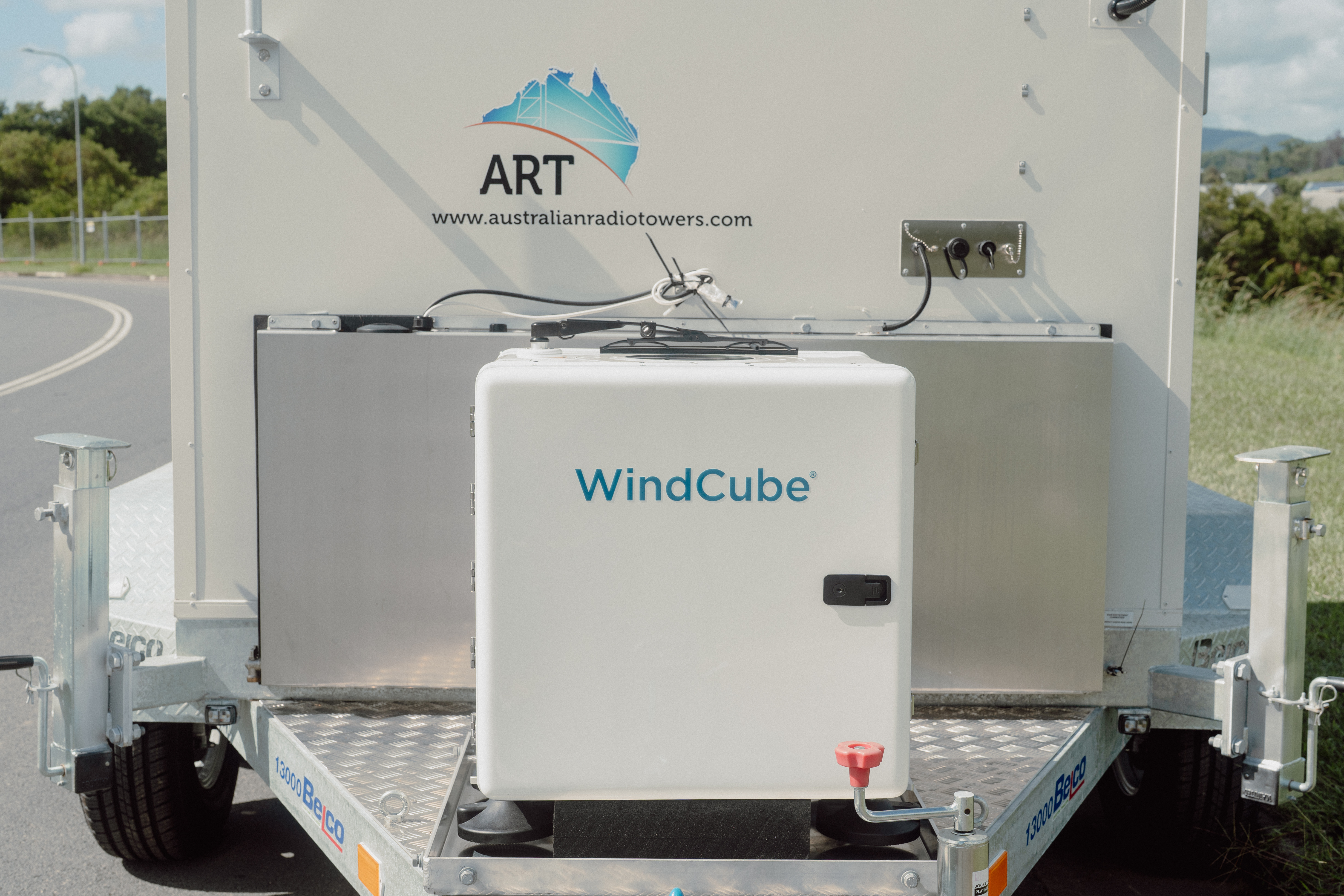

Lighthouse's portfolio companies ART and Energy3 are the wind industry's first-choice partners for securing bankable wind resource data.

- Quality environmental resource data is vital for renewable energy project evaluation and financing.

- Wind and solar campaigns involve specialised equipment, high-risk work, and strict adherence to technical standards. These complexities can lead to costly and risky endeavours for project developers.

- We offer the renewables industry turnkey solutions, including met masts, wind systems, LiDARs, and Sodars. Our services also encompass remote communication and power solutions, along with maintenance services, to ensure maximum uptime.

- ART provides comprehensive end-to-end solutions through it's market leading wind-resource-as-a-service offering. We make the complex simple.

Engineering & Design

The backbone of Lighthouse is our strong engineering expertise and capability that provides the platform for delivering smarter energy infrastructure projects both on time and to budget.

Lighthouse provides engineering and design services for products across the value chain including:

- Outdoor HV Substations

- Primary & Secondary Systems

- Overhead Powerlines

- Transportable Switchrooms

- Civil & Structural

- Power System Protection

- Power Network & Systems

- Electrical, Instrumentation & Hazardous Areas

- Plant Automation: DCS, PLC & SCADA

- Mechanical, Piping & System

- Rapid deploy communications systems

- Modular power infrastructure

- Transportable Substation & Switchroom Design

Manufacture & Supply

To manage global supply chain risks in the race to net zero, Lighthouse is scaling an onshore sovereign supply chain capability. We are expanding manufacturing within our portfolio companies to deliver Australian-made transportable switch rooms, met masts, comms towers, and modular power systems.

Our relationships with global OEMs span over 30 years, including partnerships with industry leaders. These long-standing collaborations enhance our ability to provide top-tier solutions and maintain the highest standards in our operations.

We leverage large-scale procurement to forge and strengthen long-term partnerships with global OEMs. This strategy enables us to continuously seek opportunities to consolidate and onshore our manufacturing capabilities, ensuring a resilient and efficient supply chain.

With over 90 years of continuous operation, Lighthouse companies have established extensive and robust networks with local suppliers and contractors across regional and remote Australia. This means that no matter where your project is located, we have the supply chain capabilities to deliver.

Construction

Lighthouse boasts over 1,000 skilled workers, including experienced supervisors and construction managers, ensuring that our standards and our clients' site requirements are consistently met. We specialise in operating in regional and remote areas, and our people, plant, equipment, and systems have been honed over decades of work in challenging environments.

Our core construction capabilities include:

- Turnkey cBOP and eBOP construction

- HV substation construction

- HV switchgear and switchyard construction

- Bulk and detailed earthworks

- Trenching

- Cable installation and terminations

- Powerline construction

- Transmission tower assembly and erection

- HV stringing

- Commissioning and testing

Operation & Maintenance

Lighthouse provides a range of operation, maintenance, and compliance services to ensure your energy infrastructure operates efficiently both today and well into the future.

Our companies provide a range of services including:

- Scheduled maintenance programs

- Remote monitoring and rapid response maintenance services

- Grid connection compliance management programs

Lighthouse Industries has the experience, technology, knowledge and resources to deliver the critical infrastructure services that renewable energy developers, energy utilities, and decarbonisation clients rely on.

Our experience and resources are unmatched

Project Spotlight

- Catalpa was engaged to initially deliver the early works program including replacement of an existing bridge and access track to the site, with the scope extended to include completion of the laydowns and access roads.

- Catalpa was then awarded the main BESS Package, which will include bulk earthworks, concrete works, piling and drainage.

- Catalpa committed an extensive crew of line workers to Stage 1 of the project

- This saw 203 Guyed Mast towers and 88 Suspension & Tension towers assembled & erected

33KV Overhead Line Construction

- Installation of 51 slip jointed tubular steel structures.

- Installation of all cross arms and support structures, line hardware fittings and clamps etc.

- Pre-stringing testing of all OPGW conductor Drums and OPGW Termination

- Stringing of 9.6km of single circuit overhead power line

- Stringing 7.7km of dual circuit overhead power line

Construction of the 6.8km 275kV overhead power line between the Lincoln Gap Windfarm substation and the ElectraNet 275kV Corraberra Hills switching substation.

- 6.8km of single circuit 275kV and OPGW powerline

- 27m-30m steel slip jointed tubular poles

- Installation of landing spans between the line terminal structure adjacent to both substations and the substation gantries

Design, engineer and construct 5.6km overhead High Voltage 11kv distribution powerline, to support a future centralised power generation solution at the Charo Oil Field in the Cooper Basin

- 5.6km overhead HV Transmission powerline and switchgear

- 1 x 200 kVA pole mount transformer

- 1 x 100 kVA pole mount transformer

- 8 x 63 kVA pole mount transformers

Design and construct of approximately 7.5km of 11kV overhead powerline

- 40 x 17m galvanised steel monopoles,

- 33klm of 54/7/3.0 ACSR/GZ - Mango conductors 11klm

of 72 core SMOF (Single Mode Optic Fibre) - Optical ground wire (OPGW)

- OPGW Coyotes installed at the plant and village

- Termination poles and mid-wat along the line

Design and Construct services for electrical balance of plant for the Bulgana Green Power Hub. The project consisted of 56 wind turbine generators with an installed capacity of 194MW and the connection of a 22 MVA Tesla BESS.

- Design, procurement, construction & management of a 30x6m Glass Reinforced Concrete (GRC) switchroom containing 33kV switchgear, electrical protection relays, SCADA automation & control equipment, on-load tap changer equipment & metering devices

- 33kV underground cable reticulation network connecting 56x wind turbines to 33kV switchboard, 33kV underground cables & kiosk transformers (33/0.44kV) & associated switchgear to connect Tesla BESS modules & installation of Tesla BESS battery modules & inverters

- Civil foundation design and construction

- Harmonic filter solution

A large scale windfarm electrical design package undertaken with full electrical protection design of the windfarm including engineering of all electrical components associated with collector group & switchroom. Construction & commissioning of HV protection panels.

- MV and collector group reticulation

- HV protection and integration

- Construction and commissioning of switch room and control room

- Secondary and primary commissioning of all equipment

Electrical Balance of Plant to connect 43 x 4.2MW Wind Turbine Generators, 33/132kV Substation including 33kV Switchroom, seperate 132kV Reactive Yard & O&M Building & Facility

Design, Construction & Commissioning of windfarm electrical balance of plant including five fully equipped outdoor substations.

- Designed and installed 70kms of trench

- Laid 105kms of 11kV bare earth conductor.

- Installed 105kms of 12C single and multi-mode fibre cabling into the trenches.

- Self-performed all 11kV cable and fibre optic cable terminations and joints using company-owned specialised equipment and tools.

The connection of 28 Wind Turbine Generators, 33kV electrical reticulation, Operations and Maintenance facility, communications network and high voltage wind farm substation.

- 33kV Switchroom and control

- MV/HV substation including all plant and equipment

- O&M building

- Facility protection & control system

- 30km of trenching collector reticulation system